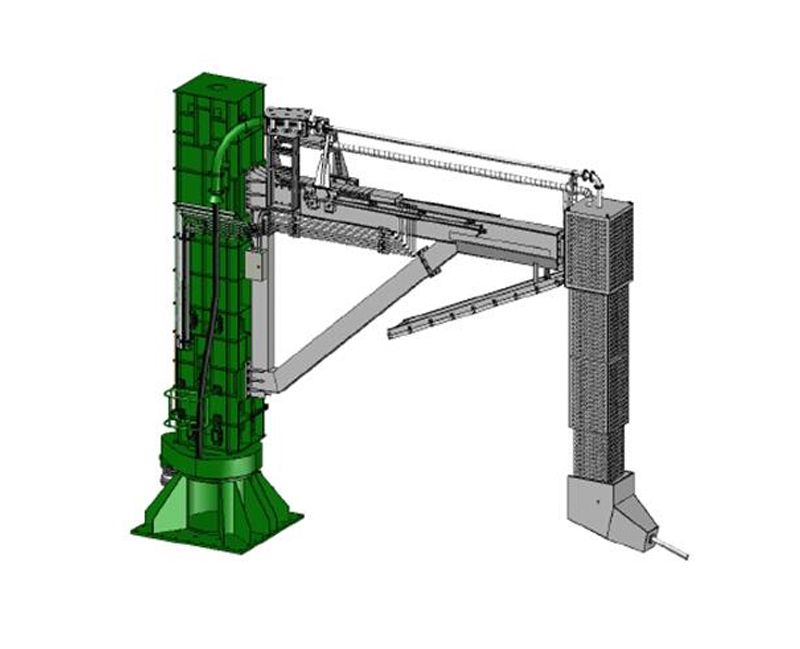

Cantilever electric furnace gunning

The cantilever electric furnace automatic repairing machine is a professional gunning equipment for repairing the damaged refractory materials of the furnace wall and furnace bottom in the steelmaking electric furnace. The machine has a high degree of automation, adopts PLC program control, and can remotely control the gunning process. The gunning quality is good and the efficiency is high, which reduces the maintenance cost of the electric furnace and prolongs the furnace life. The machine is mainly composed of furnace repair manipulator, gunning tank, hydraulic station and other parts. It does not need cleaning in daily use, and the maintenance and repair workload is small.

After the electric furnace is tapped, the gunning repair operation can be performed. At this time, the manipulator of the cantilever electric furnace automatic repairing machine starts to move. First, the cross arm of the furnace repairing manipulator is raised from the standby position and rotated to the center of the electric furnace to stop. The cross arm is lowered until the gun head is aligned with the gunning part, and the "spray button" is activated to start spraying the damaged part of the electric furnace. The gun head can not only rotate 360 degrees freely but also can be tilted 30 degrees for easy adjustment of the spray angle. The telescopic arm can be retracted to adjust the spray distance between the gun head and the furnace wall to better ensure the gunning effect. This equipment can not only carry out circumferential gunning, but also local gunning for the severely damaged parts of the furnace wall by means of spot shooting, so as to avoid wasting a large amount of charging materials and save efficiency.

Technical performance parameters

1. Gunning capacity: 80-180kg/min (adjustable spray volume, set total spray volume)

2. Adapt to particle size: ≤6mm

3. Wear-resistant hose: ¢65 mm

4. Water pipe: ¢25 mm

5. Head elevation angle: ±15°

6. The rotation angle of the gun head: 360° free rotation

7. Power supply Total power: 380V 50Hz 30KW

8. Hydraulic station: 16Mpa

9. Water pressure of water supply: >0.3 Mpa

10. Water consumption: <3m3/h

11. Compressed air pressure: >0.6 Mpa

12. Control method: wired + wireless remote control operation