玉树In 2020, Xinhongqiao High-tech Co., Ltd. realized the life of the medium and heavy plate RH dip tube in Tangshan! The annual average furnace age of the dip tube is 150! Strive for success!

Posted time:2021-09-26 Page View:15421

The Olympic Games is a higher stage for sports competition

Is the certification of the player in the field

But there is another kind of achievement whose value goes beyond

That is - breakthrough

A record is broken

in competitive sports

It is the perfect display of human breakthrough

in the field of social development

It is the result of technological innovation and technological innovation

Recently, the No. 5 dipping tube of the RH vacuum refining furnace B of Hegang Tangsteel Medium and Heavy Plate Company went offline, during which a total of 228 furnaces of molten steel were smelted, setting a record for the service life of the domestic RH dipping tube.

RH vacuum refining furnace

Using vacuum technology to reduce the gas content in molten steel, it is widely used in the production of high-end, high-value-added and high-quality products such as high-strength building steel, bridge structural steel, pressure vessel steel, and weathering steel.

The lower part of the vacuum tank of the RH vacuum refining furnace is connected with two dipping pipes with refractory materials, and its life directly affects the stable and efficient operation of the equipment and the production cost.

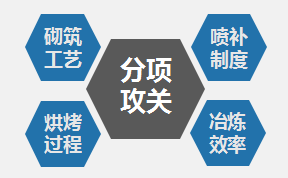

HBIS Tangsteel Medium and Heavy Plate Company has specially set up a research team for the life of RH dipping pipes, and has carried out sub-item research on dipping pipes.

During the operation, the key links such as the masonry method of reserved expansion joints at the bottom of the tank, the preheating technology of the immersion pipe, the slag repair technology of the immersion pipe, the maintenance technology of the dead angle of the immersion pipe spraying, and the baking sealing technology are continuously optimized.

At the same time, through continuous research and improvement, the company has greatly improved the vacuum treatment efficiency of the RH furnace, reduced energy consumption, and reduced the overall cost by 3.9 yuan/ton.